The purpose of this oil hole and seal really baffled me and was a problem since I needed to know what it really did in order to know if it was needed in my engine too.

Going to the world's largest image library, the internets, I was able to solve the mystery. There is a nicely documented teardown of an earlier year Panigale engine here.

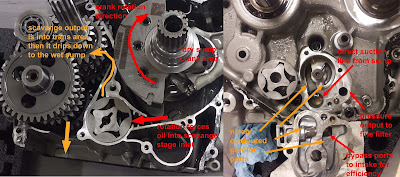

This image in particular (text/arrows are my addition) was what made everything clear:

Seeing this, I dug into a few different year Panigale microfiches at the AMS Ducati Dallas website. There was a forced oil feed for the transmission output shaft on all the 1199 models up to the MY2014 but it was eliminated in MY2015 and later when they went to the 1299. My 2016 1299 crankcases are not tapped for the oil tube mounting holes so I will not worry about trying to get pressurized oil there.

Saturday, December 28, 2019

Friday, December 27, 2019

Dissecting the Panigale Engine

While taking the engine apart it is nice to look around the insides and see what clever details the Ducati engineers have figured out. Of the two major changes in the engine design that were implemented in this new engine, one is nearly invisible and one is highly visible: two stage oil system and chain/gear drive camshaft actuation. I will review the oil system in this post.

The oiling system underwent a major redesign for this engine. I would describe it as a hybrid dry/wet sump system. The crankshaft cavity is well sealed similar to a two stroke crank area. It is so well sealed that it is difficult to turn the crank by hand, even with both cylinder heads off! You can hear the blowby similar to a compression stroke on a fully assembled engine. This is not a problem during actual operation because you can see the new crankshaft scavenge stage is much larger than the pressure stage so during operation there would be a low vacuum in the crank mains area.

The oil pump works as shown in the attached image, the output of the scavenge serving to oil the trans before draining to the sump. It is a clever design that makes the most of the pumping action of the scavenge stage and gives the return oil plenty of time to deaerate.

The sump then has a direct line to the intake of the pressure stage, then out to the fine filter, then into the oil galley to feed the rest of the engine. Camshaft oiling is similar to the previous designs with the addition of line running to a hydraulic cam chain tensioner for each head.

One feature I am unsure of is on one end of the transmission output shaft. It is a small roller bearing and there is a 6mm hole drilled in the crankcases that nothing goes into and is obscured by the clutch primary drive gear.

What I am unsure of is that that end of the transmission shaft has an

oil seal installed. There does not seem to be anything that goes into

the seal so I am baffled as to it's presence. Anybody have ideas? There is no access to any other parts of the oil system through this bearing pocket or the rest of the trans shaft.

The oiling system underwent a major redesign for this engine. I would describe it as a hybrid dry/wet sump system. The crankshaft cavity is well sealed similar to a two stroke crank area. It is so well sealed that it is difficult to turn the crank by hand, even with both cylinder heads off! You can hear the blowby similar to a compression stroke on a fully assembled engine. This is not a problem during actual operation because you can see the new crankshaft scavenge stage is much larger than the pressure stage so during operation there would be a low vacuum in the crank mains area.

The oil pump works as shown in the attached image, the output of the scavenge serving to oil the trans before draining to the sump. It is a clever design that makes the most of the pumping action of the scavenge stage and gives the return oil plenty of time to deaerate.

One feature I am unsure of is on one end of the transmission output shaft. It is a small roller bearing and there is a 6mm hole drilled in the crankcases that nothing goes into and is obscured by the clutch primary drive gear.

A Glance at the Past

After letting the MC Chassis Design internet mailing list know about the new projects, Robert Horn, of FF/FFE fame, sent me a link to a RoadracingWorld piece about the V4 project in 2011.

I nearly forgot about this article but it nicely covers all the details about the inception of the V4 from the single. The title leaves a little to be desired but it gave the project some good coverage. Maybe there will be an updated article when this bike is finished.

I nearly forgot about this article but it nicely covers all the details about the inception of the V4 from the single. The title leaves a little to be desired but it gave the project some good coverage. Maybe there will be an updated article when this bike is finished.

Monday, December 23, 2019

Engine Teardown, Part 1

- The clutch cover had a sound dampening assembly in the cap that was about 3/4" thick, a pretty significant amount.

- The cam chain guides were retained with bolts using o-rings to prevent rattle.

- The primary drive gear had a spring loaded floating gear to eliminate gear rattle at low speeds

- The clutch had a thin section belleville spring on the clutch hub to keep the friction pack from rattling when disengaged.

After all that effort to reduce mechanical noise, they used roller cam chains instead of 'silent' cam chain. I wonder if the silent style chain was not strong enough.

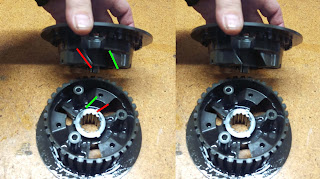

Getting the side covers off, then removing the clutch and generator is one more layer of the onion off. The OEM slipper clutch had only 3 springs but were assisted by a significant self-locking design on the slipper clutch hub. Not only did the hub have a negative ramp that opened the clutch pack to create slippage when negative torque is applied, it also has a positive ramp which acts to tighten the pack pressure when slippage occurs when positive torque is applied.

Once all the covers and ancillary components were removed, what remained was what was really of interest: shaft center locations.

By careful measuring and use of 3D scanning techniques I will establish the relationships between the various shaft centers. This information will be transferred to CAD as a simple 2D sketch that can then be used as the basis of the new engine design

This may seem like a simple 2D drawing, but it contains most of the important engine dimensions has 'hidden' information which drives downstream relationships in the CAD model.

From the initial inspection it seems to make sense to use the following components/subsystems:

- cam drive system

- oil pump system

- generator/starter assembly

- cylinder head

- transmission

- shifter mechanism

- piston/cylinder liner

- crankcases

- crankshaft

- connecting rod

- counterbalance shaft

- water pump

- oil passage system

The water pump will be an external on-demand electric pump supplied by Davies Craig. I use this technology in the existing Rotacular with excellent results and temperature control with no need for duct tape on the radiator. Seeing how much space is taken by the water pump (2 stage gear reduction) and the thermostat/distribution manifold, I am surprised that Ducati did not go a electric route. They have the radiator, fan, shroud, and hose assembly design as a complete assembly that can be removed as a unit. Integrating an electric pump would be a snap and simplify the overall routing.

The other decision to make is which head to use, the horizontal or vertical one.

The vertical head as two robust mounts used for the subframe that could be repurposed for a front engine mount but the decision will be driven by which side the cam drive and generator systems are cleanest to integrate into.

Once all of these shaft centers and their components are measured and put into the new arrangement, the crankcases are designed by creating an envelope around the parts, adding thickness to it, then adding ribs and gussets for strength.

So a little measuring and a lot of thinking are on my to-do list for the next couple of weeks. I'll post updates as items become resolved.

Also, here is a nice gallery of disassembled Panigale engine pictures

Chris

Sunday, December 22, 2019

Doubling down on 2020

After a difficult 2019 there was about a microsecond thought about scurrying away from the track with my tail between my legs. However, common sense was locked in the basement and this year we're chucking in everything, including the kitchen sink.

First news is that a new single is in

process, the Hypermono. Second is that I’ll also be making a full mock-up of the V4

in the hope of drumming up interest to get it into running condition. Third is there will be several racing events

on the calendar, starting out using the Rotacular and with the Hypermono rolling

out by June. I’ll try to have a fast rider on it for the AHRMA Barber

event in Oct that can challenge for the win in the open singles class,

SoS1.

Having this all happen so quickly was a lot for me to digest. A few seconds later plans were fully developed and in process. A pretty wrecked but running and complete 2016 1299S to use

as a donor appeared and the clock has started ticking.

I will

be also IGing it with the hashtag #hypermono which will be mostly visual but most of the content will

be posted here. Lots of text does not go over

well with the IG crowd.

The V4 will be a complete, non running version of the full bike, which has been amply documented on this blog.

The single will use the V4 FFE/idler rolling chassis, which initially was hijacked

from the Ducati 1098-based single that never make it past CAD. The

1098-based bike was supposed to be the successor to the existing Rotacular but

the V4 took over, then fell prey to various factors beyond my control.

Sometimes shit happens. Fortunately, motorcycle suspension has not

changed in the past 10 years, so comparatively my design is as advanced today

as it was 10 years ago. Sigh. For the swingarm I am thinking of

doing a one piece aluminum sand casting using a 3D printed sand mold from Hoosier

Pattern or Humtown and cast locally. Then post-machining using the

trunnion table on my VMC. The largely complete chassis design also lends

itself to fitting a big battery and motor so you never know want else might

come out of the shop.

1999-2001- The Start Of It All: racing RS125 and TZ250 CCS/LRRS and USGPRU

2002-2006- Getting In Deeper: building and racing the first two version of the Rotacular

2007- How Deep Is This Hole?: designing the Ducati 1098 based successor to the Rotacular

2008-2009- Delusions Of Grandeur: 250GP class changed to Moto2. The initial rules were for open engine specification, so I got an investor on board, jumped in and designed a 600cc V4 that used cut-in-half ZX-6R heads from an Attack Kawasaki Formula Xtreme bike. The engine would fit nicely into the nearly complete rolling chassis design for the 1098-based single cylinder engine. About 6 months later, news came out that Moto2 would use a spec CBR600 engine, dashing any hopes of us getting into the GP paddock and forever relegating the middleweight Grand Prix class to irrelevance.

2010-2019- Licking Wounds: Having dumped all my resources in to the V4 project, emerging into a recession-hit economy was not the best exit plan. I recouped, ran down some new business, unrelated to motorcycles, yet kept tinkering in CAD in the hope it would all come good again. And being happy that said investor takes a calm, long term view of things!

2020-It All Comes Good Again: I repeat, it all comes good again. And wow, that was 20 years of my life!

I now have everything needed to get the project started, so watch this space as it all comes together over the next 6 months.

Chris

Subscribe to:

Comments (Atom)